▷ Reduced wall thickness for thin-wall packaging - ENGEL Blog

4.8 (687) · $ 10.50 · In stock

Reduced wall thickness for thin-wall packaging ✓ Which challenges the developments place on the injection moulding process ➠ Read more

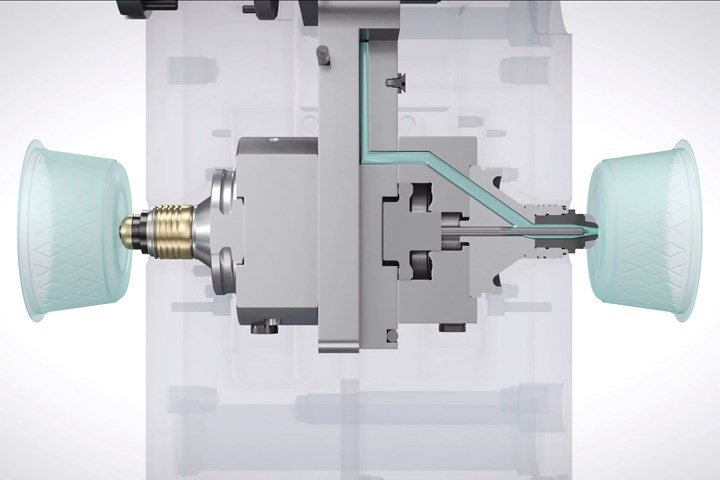

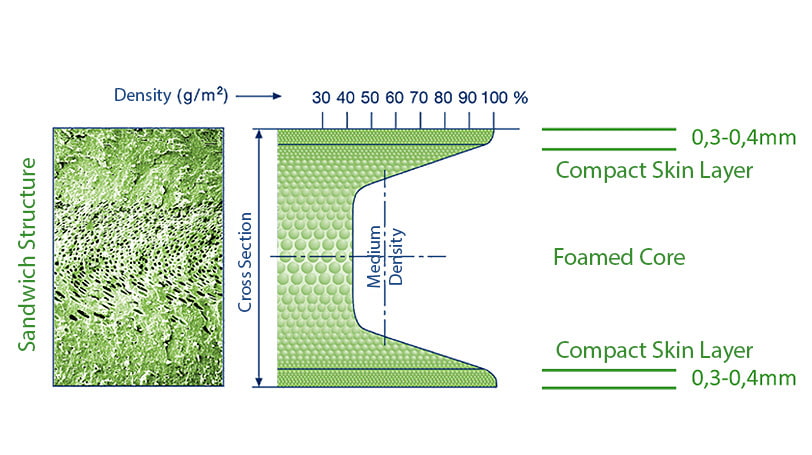

The ever-advancing weight reduction of packaging through reduced wall-thickness is an ongoing topic in the packaging industry, which is constantly increasing the demands on injection moulding machines.

ENGEL and partners develop single injection moulding process for

▷ Production of plastic packaging - ENGEL

)

▷ Solutions for thin wall injection moulding - ENGEL

)

▷ Injection molding process for lightweight parts - ENGEL

▷ Injection moulding machine for thin-wall plastic - ENGEL

▷ The basics of foaming plastics foammelt - ENGEL Blog

▷ Production of plastic packaging - ENGEL

▷ Energy efficiency in the packaging industry - ENGEL Blog

▷ Injection-compression moulding of thin-walled containers - ENGEL Blog

Direct processing of rPET in thin-wall injection moulding with

)

▷ Injection moulding machine for thin-wall plastic - ENGEL

)

▷ Injection molding process for lightweight parts - ENGEL

)

▷ Solutions for thin wall injection moulding - ENGEL

Gas-tight means zero defects - design considerations for thin

▷ Reduced wall thickness for thin-wall packaging - ENGEL Blog